Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Production Visualisation Overall Equipment Effectivness (OEE)

Production Visualisation Overall Equipment Effectivness (OEE)

Increase value creation, minimise waste

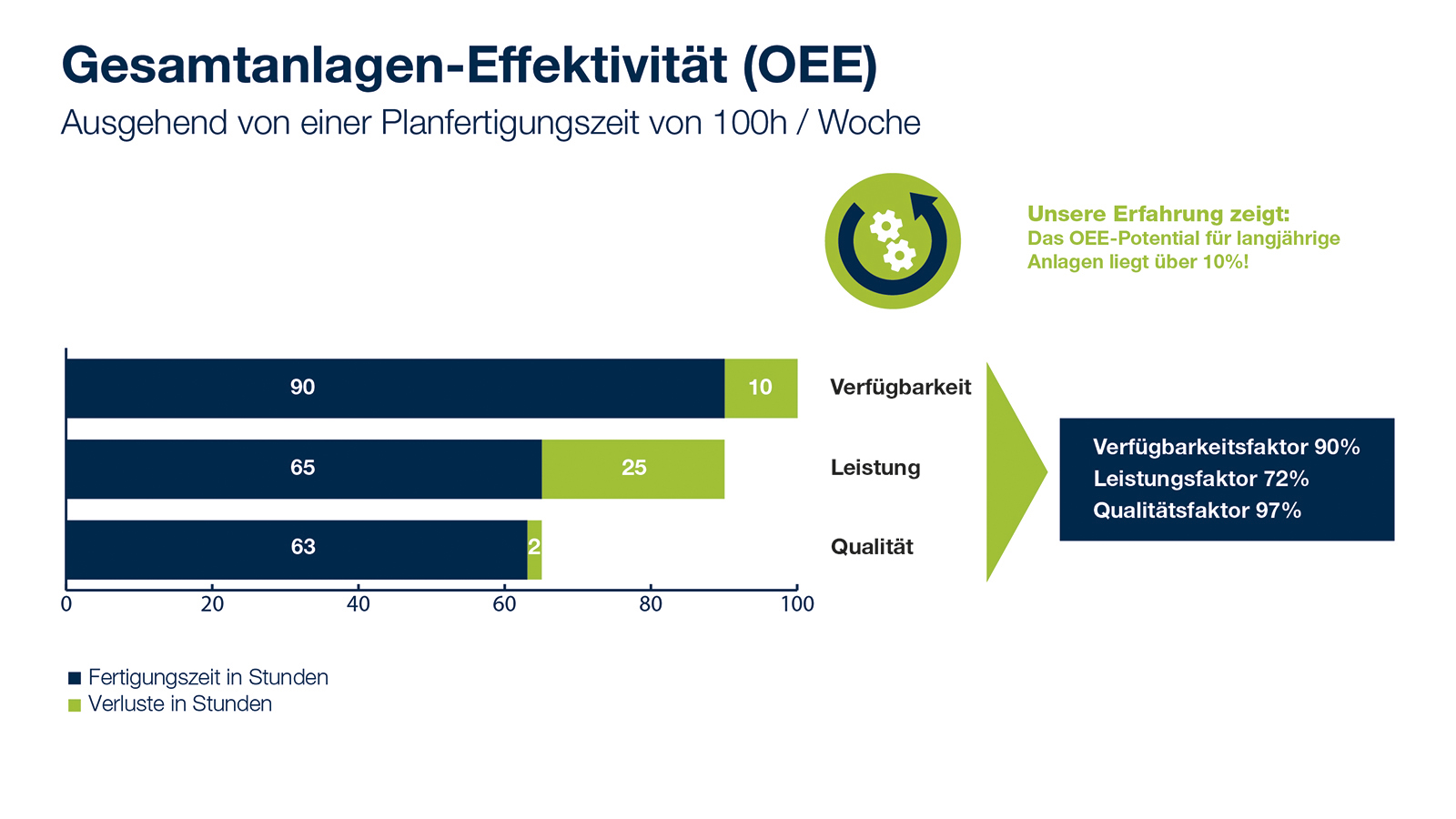

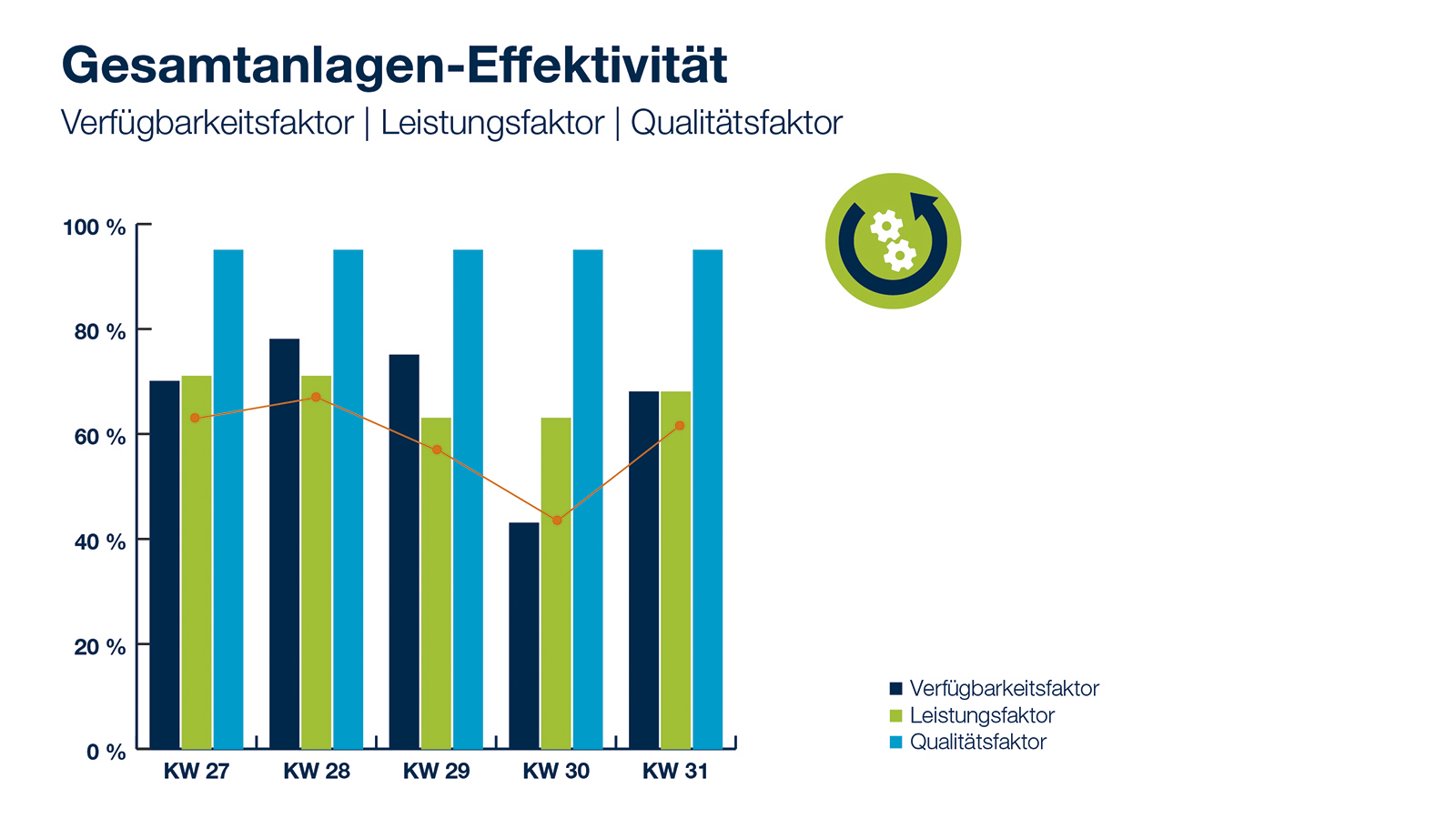

Overall Equipment Effectiveness (OEE) is a key figure that is composed of the factors availability, performance and quality. This key figure includes the most essential elements that have an influence on productivity and thus on the economic efficiency of your processes and plants.

Images

Features

-

With Lean Six Sigma, we elaborate optimisation proposals that increase your overall plant effectiveness and proceed in five steps:

- Define: We capture the initial situation and make it measurable.

- Measure: We capture your data and measure the current process performance.

- Analyze: We identify and evaluate root causes.

- Improve: Together we develop solution concepts for your production.

- Collaborate: Together we implement solution concepts for your production.

Here's how your colleagues produce

Brochures